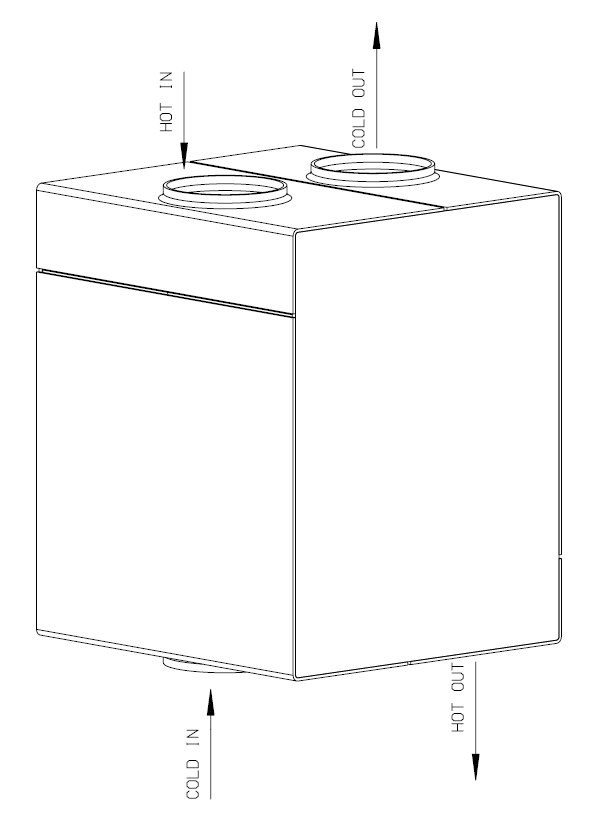

P5-LPD-100

BOSAL Energy offers welded, compact plate heat exchangers for high temperature applications. The heat exchanger line is modular, and is available by default in high-end stainless steel. For the most demanding applications we offer products entirely made out of Ni-alloy. The Bosal heat exchangers are highly effective and are suitable for high temperatures (up to 950ºC/ 1742ºF) with limited Cr evaporation and metal dusting.

Application

Suitable for a wide range of applications, such as:

• Fuel cell systems (SOFC, SOEC, PEMFC, MCFC)

• Chemical Processes

• Gas turbines

• Micro gas turbines

• Stirling engines

• Internal combustion engines

Benefits

• High effectiveness and low pressure drop

• Compact

• Easy to install

• Optimized for lifetime

• Upgrade to Ni-alloy version for the most demanding applications

• On-demand catalytic coating for combined heat exchange and steam reforming, oxidative reactions, ammonia cracking.

• On-demand protective coatings for limiting Cr evaporation, increased resistance to corrosive conditions or high temperature.

Design

• High quality robotized welding (Laser, MIG/MAG)

• Validation tested using highly sophisticated infrastructure

• Manufacturing and process engineering expertise

• Fully integrated Hot Balance of Plant system design capabilities

• Customized designs for high production volume